Plywood vs. Particle Board in Custom Kitchen Cabinetry

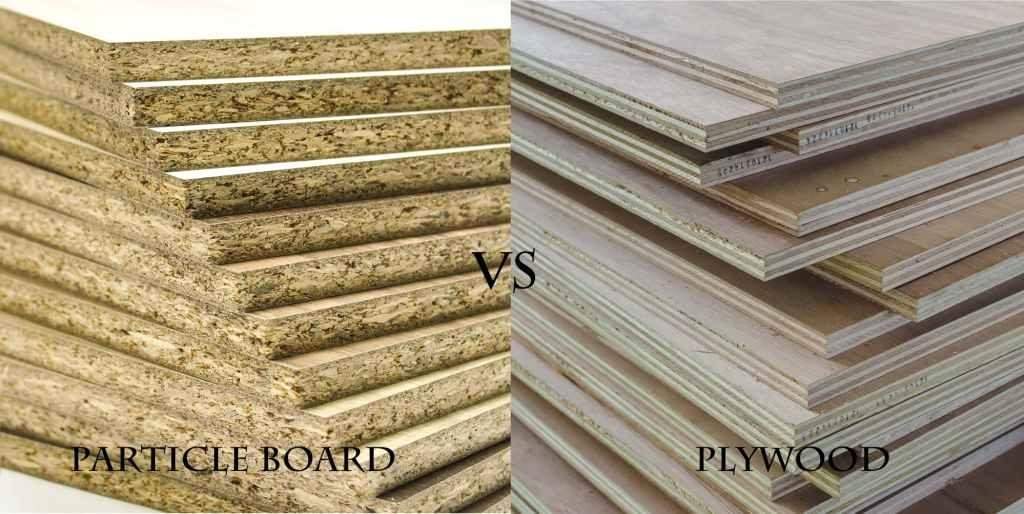

Plywood vs. Particle Board

What’s the difference and which material is best for your custom cabinetry?

When it comes to choosing the right construction material for your cabinetry, the debate often boils down to two popular options: plywood and particle board. Both materials have their merits and drawbacks, but understanding the differences can help you make an informed decision for your next project. Whether you’re outfitting a high-end residential kitchen or a commercial space, selecting the right material is crucial to the longevity and aesthetic of your cabinetry.

What is Plywood?

Plywood is an engineered wood product that has been a staple in construction, cabinetry, and furniture making for decades. It is made by bonding together thin layers of wood veneer, known as “plies,” with strong adhesives. These layers are arranged so that the grain of each ply is perpendicular to the next, creating a cross-laminated structure. This unique arrangement not only enhances plywood’s strength and stability but also helps in evenly distributing the stress across the entire sheet.

Production Process

The process of making plywood begins with selecting logs, which are then peeled into thin veneers. These veneers are dried to reduce moisture content, ensuring that the final product is stable and durable. After drying, the veneers are layered and glued together, with each layer’s grain running in a different direction. This cross-graining technique minimizes wood movement and improves the sheet’s resistance to splitting. The glued veneers are then pressed under high pressure and heat to cure the adhesive, forming a solid, stable sheet of plywood.

Grades of Plywood

Wedgewood hand picks our plywood from lumber yards, selecting only the highest quality and most beautiful pieces available. When building with plywood, we use A-Grade from local sources.

Plywood comes in different grades, which reflect the quality and appearance of the veneers used:

- A-Grade: The highest quality, A-grade plywood has a smooth surface with few to no defects, making it ideal for projects where appearance matters, such as cabinetry and furniture.

- B-Grade: B-grade plywood has a solid surface with minor flaws, such as small knots, but is still suitable for high-end uses where the surface will be visible.

- C-Grade: C-grade plywood has noticeable defects like larger knots and splits. It’s often used for structural purposes or in areas where the surface will be covered.

- D-Grade: D-grade is the lowest quality, with visible defects. It’s typically used for structural applications where appearance is not a concern.

Types of Plywood

- Softwood Plywood: Made from softwood species like pine or fir, softwood plywood is commonly used in construction for sheathing, subfloors, and roof decking.

- Hardwood Plywood: Produced from hardwood species such as oak, birch, or maple, this type of plywood is used in cabinetry, furniture, and high-end millwork.

- Marine Plywood: Designed for use in wet environments, marine plywood is made with waterproof glue and high-quality veneers, making it highly resistant to moisture and rot.

- Structural Plywood: Engineered to bear heavy loads, structural plywood is used in construction projects requiring significant strength and durability.

Pros of Plywood

- Strength and Durability: Plywood’s cross-laminated structure gives it exceptional strength, making it suitable for load-bearing applications and high-traffic areas.

- Moisture Resistance: With its ability to resist moisture better than particle board, plywood is less prone to warping and swelling in humid environments.

- Screw Holding Capacity: The layered construction of plywood offers superior screw-holding power, which is crucial for assembling and disassembling cabinetry.

- Aesthetic Appeal: Plywood’s natural wood grain can be easily stained or finished, providing a high-end look that is particularly desirable in custom cabinetry and furniture.

- Lightweight: Plywood is lighter than particle board, making it easier to handle, transport, and install.

Cons of Plywood

- Cost: Plywood is generally more expensive than particle board, which can increase the overall cost of your cabinetry or furniture project.

What is Particle Board?

Particle board is another popular engineered wood product, but it differs significantly from plywood in both composition and performance. It is often used as a more cost-effective alternative to plywood, particularly in applications where exceptionally high strength is not required. Particle board is the standard construction in the cabinetry industry.

Production Process

The manufacturing process for particle board involves collecting wood waste materials like chips, sawdust, and shavings, which are mixed with resin and compressed under high pressure to form sheets. After the sheets are formed, they are sanded to create a smooth, even surface, making them ideal for laminates and veneers.

Pros of Particle Board

- Affordability: Particle board is generally less expensive than plywood, making it an attractive option for home renovation projects.

- Smooth Surface: The uniform texture of particle board makes it ideal for applications where a smooth, even surface is needed, such as when applying laminates or veneers.

- Abundance: Particle board is readily available from local and national sources, helping to keep lead times down, as well as reducing costs.

Cons of Particle Board

- Less Strong: Compared to plywood, particle board is less durable and more susceptible to damage, especially under heavy loads or impact.

- Moisture Vulnerability: Particle board’s susceptibility to moisture can lead to swelling, warping, and eventual breakdown, making it unsuitable for areas prone to humidity or water exposure.

Which material should you choose?

When deciding between plywood and particle board, consider the specific needs and conditions of your project. Particle board is the standard construction for residential spaces, even in high-end luxury homes. Meanwhile, when budget allows, plywood is often the preferred choice for jobs that demand strength, durability, and moisture resistance. Its superior performance in demanding environments makes it a top pick for designers and builders who prioritize quality. On the other hand, if your project is more budget-sensitive and doesn’t require the heavy-duty attributes of plywood, particle board can be a practical alternative. It’s particularly suitable for interior applications where moisture exposure is minimal and the demands on structural strength are moderate.

In summary, both plywood and particle board have their place in the world of cabinetry and construction. The key is to match the material to the specific requirements of your project, balancing cost, strength, and durability to achieve the best results.

Latest Articles

Custom Woodwork From Our Craftsman’s Bench to Your Home

Wedgewood Cabinetry is the highest quality custom cabinetry in Colorado. Our wood is locally sourced, which means it’s acclimated to the unique Denver climate, minimizing expansion, contraction, and discoloration throughout the entire lifespan of the cabinets. We offer exotic wood and inlays with unlimited design options, even providing our unique cabinet designs in a wide variety of material outside of wood, giving our Denver customers the unlimited potential to complete the look of your dreams.